Table Of Content

At least three bolt, nut, and washer assemblies from each lot is tested to verify the bolts’ ability to develop the required tension. Plumbing steel is aligning for compliance with erection tolerances, generally +/- 1 inch horizontal or 1 in 500 units of height. Crews typically use a transit, a two-foot offset, and diagonal guy cables with turnbuckles. Paired Power, a commercial solar and battery energy storage system manufacturer, received a $3.5 million tax credit to expand its operations in Campbell as well as the Central Valley. In exchange for this tax credit, the company is expected to make capital investments of more than $540 million and create nearly 450 new jobs. SACRAMENTO – As part of the California Jobs First initiative, Governor Gavin Newsom today announced that the state has awarded $120 million in tax credits to eight innovative companies.

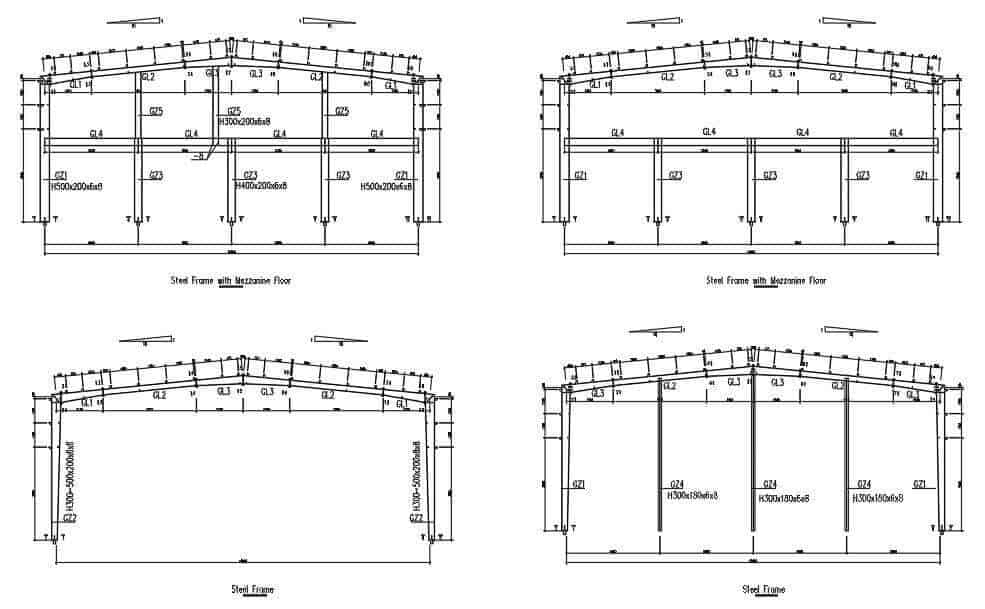

Commercial Metal Buildings

Three main methods are used in tension bolted connections to verify correct values. The turn-of-nut method requires bringing the nut to a snug-tight condition and then further tightening an additionally 1/3 to one full turn, depending on the length and diameter of the bolts. Contractors consider turn-of-the nut as the most reliable and preferred method. The calibrated wrench method uses wrenches set to provide bolt tension at least five percent greater than prescribed minimum bolt tension. This method requires returning to further torque after tensioning all bolts.

Metal Structure Warehouse Buildings

AA Metal Buildings is home to a wide inventory of metal buildings; whatever you need, we can supply! When you're looking for high-quality steel structures that can be customized to your unique requirements, look no further than the experts at AA Metal Buildings. The design process encompasses the architectural design, the development of the structural concept , the analysis of the steel structure and the verification of members.

Design, Configure, and Price Steel Buildings Online with our 3D Building Design Tool

When the stability of the structure is provided by cores, or discreet vertical bracing, the beams are generally designed as simply supported. The generally accepted design model is that nominally pinned connections produce nominal moments in the column, calculated by assuming that the beam reaction is 100 mm from the face of the column. Our 3D steel building designer can give you a blank template or a base model to begin to design steel structures. Detailing of structural steel is now performed primarily in 2D AutoCAD with increasing use of 3D. Several sources and activities provide key design criteria for detailing. These include standards; coordination with structural, architectural, and MEP drawings; and the desire to maximize shop connections as limited by maximum shipping size of pieces and capacity of the crane planned for erection.

Modern, durable structures customized to YOUR exact needs

Publications that contain such design guidance may be referenced in the National Annex as NCCI. In addition to the Eurocodes and the National Annex, non-contradictory complementary information (NCCI) is provided, to provide further guidance on the application of the Eurocodes. All frames must be assessed for sensitivity to second-order effects, and these effects allowed for if necessary. Although manual methods of analysis may be used, most designers find it convenient to use readily available software . Glazing systems Generally triple glazing or double layer facades supported on aluminium posts or glass fins.

Our Building Specialist will contact you soon to assist and design your dream metal building. Satisfaction – At AA Metal Buildings, your satisfaction is our priority! Our friendly experts are available to you every step of the way, and we encourage you to call us with any questions you may have. We want you to love your new metal building; we won't be satisfied until you are satisfied. Parking space – Maneuverability is optimized with no interior column cluttering your space!

The scope of structural steel work typically consists of the steel elements of the building frame shown on the design drawings, which are essential to support the design loads. Contracts for steel erection typically require others to provide site access, prepare the overall schedule, and identify and manage interfaces with other construction trades. Steel structure design principles refer to the basic principles that should be followed in designing steel structure buildings. The most basic tenets are safety and reliability, which means that the structural design must ensure the stability and strength of the structure under the specified working load. In addition, the economy and aesthetics of the system also need to be considered. Our curated gallery below showcases diverse 3D renderings from our extensive portfolio, featuring both residential and commercial projects.

Our advanced engineering capabilities provide design with fewer parts, and our smart, ready to construct systems provide a fast, economical way to build your next self storage project. Unlike most Metal Building Companies we can design, engineer and construct Metal Storage Buildings ranging from one to several stories and with a wide range of floor plan choices. We meet our customer's needs in constructing their Metal Buildings that maximize space efficiency and increase rental income potential. Why choose to partner with Pacific Metal Buildings for your residential, agricultural, and commercial metal building needs in California and Oregon? We’re a multigenerational business headquartered in Maxwell, CA, and we’ve specialized in providing quality metal structures for our local region since 2009.

12 projects earn structural steel industry's top building award - Building Design + Construction

12 projects earn structural steel industry's top building award.

Posted: Mon, 30 Mar 2015 07:00:00 GMT [source]

For more complex structures, or innovative designs, best practice is to develop the structural concept in conjunction with the architectural scheme, so that an efficient, appropriate solution can be developed. Flux cored arc welding (FCAW) uses a continuous filler metal electrode that is automatically fed as wire from a role. The tubular electrode contains core ingredients that supply some or all the shielding gas needed. Gas-shielded flux core processes include an external gas supply to supplement shielding from the core. Self-shielded electrodes provide full shielding from protective gases and slag. The most widely used welding process for carbon and low alloy steels as well as stainless steel is shielded metal arc welding (SMAW), also known as stick welding.

Braced steel cores may be used as an economic alternative where speed of construction is critical. Because of its high speed and portability, FCAW is widely used in construction. Potential problems include melted contact tip, irregular wire feed, and porosity.

This updated design guide updates AISC’s resources for HSS connection design, greatly expanding upon the background discussion for each connection. The thorough explanations of the relevant limit states and the experimental results for each connection lend the reader an invaluable insight into the rationale behind each connection design procedure. The expanded guide includes many new connection types and a dozen new design examples. The characteristic values of loads depend on a lot of different factors like location, National Annex and geometry of the building and roof to name just a few.

No comments:

Post a Comment